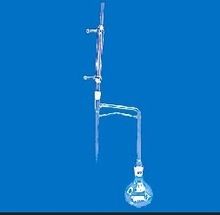

All Glass Distillation Apparatus

Price 26000 INR/ Piece

All Glass Distillation Apparatus Specification

- Temperature Range

- Ambient to 100C

- Accuracy

- High precision in distillation

- Measurement Range

- Suitable for lab-scale distillation

- Voltage

- 220V

- Power Source

- Electric

- Frequency

- 50 Hz

- Feature

- All-glass construction for purity

- Warranty

- 1 year

- Automation Grade

- Manual

- Capacity

- 500 ml to 1 liter

- Model No

- AGDA-500

- Core Components

- Glass Heating Coil

- Equipment Materials

- Borosilicate Glass Metal Base

- Type

- Distillation Apparatus

- Usage

- Chemical and laboratory distillation

- Dimension (L*W*H)

- Compact size (approx. 30x15x20 cm)

- Weight

- Approximately 3 kg

About All Glass Distillation Apparatus

All Glass Distillation Apparatus

Distillation Apparatus All Glass Distillation Apparatus All Glass Is The Assembly Consists Of A Corning Glass Flask With Embedded Heating Elements Fused In Spiral Type Glass Coil Internally At Bottom. A Double Wall Coiled Condenser Has Standard Ground Glass Joints. Complete With Glass Fitting, Metallic Stand, Rings Clamps And Electrical Fittings. The Unit Supplied Is As Per Npl Patent Design. To Work On 220/230 Volts A.C. Supply.

Flask Capacity Single Stage Double Stage Triple Stage

A) 3Lit.Cap.

B) 5Ltr.Cap

I) Thermal Sensor Cutoff Device : For Single Unit

Ii) Thermal Sensor Cutoff Device : For Double Unit

Iii) Thermal Sensor Cutoff Device : For Three Unit

Iv) Special Grade Rubber Tubing (Coil Of 10 Meter)

Exceptional Purity with All-Glass Construction

Featuring a robust borosilicate glass design, the AGDA-500 distillation apparatus ensures contamination-free distillation processes. The all-glass construction makes it an ideal choice for chemical, pharmaceutical, and educational laboratories that demand high purity and chemical resistance for accurate results.

Precision and Reliability for Lab Use

This apparatus delivers high-precision distillation at temperatures ranging from ambient to 100C. Its manual operation allows users to carefully control the process, while the electric power source and compact footprint (30x15x20 cm) save valuable lab space. The AGDA-500 consistently provides reliable outcomes for small-scale distillation needs.

FAQs of All Glass Distillation Apparatus:

Q: How does the all-glass distillation apparatus ensure purity in chemical distillation?

A: The apparatus is constructed entirely from borosilicate glass, which is chemically inert and minimizes contamination, ensuring that all distilled products maintain high purity, critical for laboratory and chemical applications.Q: What is the recommended process for using the AGDA-500 distillation apparatus?

A: Begin by adding the appropriate volume of liquid (500 ml to 1 liter) to the vessel, turn on the device using the 220V electric power source, and manually monitor the distillation process. The heating coil will raise the temperature up to 100C, allowing for precise separation of components.Q: When should I choose manual distillation over automated solutions in my laboratory?

A: Manual distillation is preferable when direct monitoring and control over the distillation parameters are needed, ensuring accuracy in smaller lab-scale operations, sample preparation, or research involving sensitive substances.Q: Where is the best place to install the distillation apparatus in a laboratory setup?

A: Install the AGDA-500 on a stable, heat-resistant laboratory bench, ensuring proximity to power outlets (220V) and adequate ventilation. Its compact dimensions make it suitable for limited spaces in research labs or pilot setups.Q: What are the key benefits of using this apparatus for laboratory distillation tasks?

A: Key benefits include high precision, purity from all-glass components, chemical resistance, and flexibility in capacity from 500 ml to 1 liter, making it highly suitable for diverse distillation processes in scientific and educational environments.Q: How can I maintain the distillation apparatus to ensure long-term reliability?

A: After each use, clean all glass components with appropriate laboratory cleaning solutions, ensure no residues are left, and inspect the heating coil and connections. Regular maintenance, as per the manufacturers guidelines, helps maximize the apparatuss performance and longevity.Q: Is this apparatus suitable for export, and who can benefit from its use?

A: Yes, the AGDA-500 is suitable for export and is manufactured and supplied in India. It benefits research institutes, universities, pharmaceutical labs, and chemical industries seeking reliable, pure distillation in compact lab environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Laboratory Apparatus Category

Bulk Density Apparatus

Price 9500 INR / Piece

Minimum Order Quantity : 1 Piece

Core Components : Motor, Timer, Measuring Cylinder, Platform

Capacity : 100 ml, 250 ml, 500 ml cylinders

Automation Grade : SemiAutomatic

Dimension (L*W*H) : 60*45*20 Centimeter (cm)

Friability Test Apparatus

Price 9500 INR / Piece

Minimum Order Quantity : 1 Piece

Core Components : Motor Display Panel

Capacity : 1 3 Tablets

Automation Grade : SemiAutomatic

Dimension (L*W*H) : Compact design suitable for laboratory use

Clevenger Apparatus

Price 3300 INR / Piece

Minimum Order Quantity : 1 Piece

Core Components : Condenser graduated tube boiling flask

Capacity : Varies depending on glassware setup; typically 100200 ml

Automation Grade : Manual

Dimension (L*W*H) : Standard laboratory glassware dimensions

|

ESEL INTERNATIONAL

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry