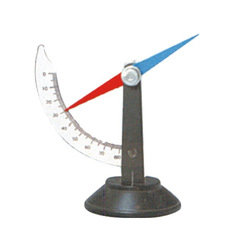

Dip Needle

Price 4500 INR/ Piece

Dip Needle Specification

- Equipment Materials

- Iron & Bakelite

- Usage

- For Laboratory

- Capacity

- 1 Kg/hr

- Temperature Range

- 10-40 0C Celsius (oC)

- Display Type

- Analog

- Dimension (L*W*H)

- 8*4*2 Centimeter (cm)

- Weight

- 300 Kilograms (kg)

Dip Needle Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- Ambala cantt

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 1 Piece Per Week

- Delivery Time

- 1 Days

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Packaging Details

- Each Piece

- Main Export Market(s)

- Africa, Asia

- Main Domestic Market

- All India

- Certifications

- ISO 9001..2015/CE

About Dip Needle

Dip Needle

The rotating, magnetized steel needle aligns with the direction of the earth's magnetic field when no other magnetic field is present. in its horizontal position, it can be used as a conventional compass.

The Dip Needle is a compass pivoted to move in the plane containing the magnetic field vector of the earth. It will then show the angle which the magnetic field makes with the vertical. The needle must be accurately balanced so that only magnetic torques are exerted on it.

Robust Construction for Precision

Crafted from iron and Bakelite, the Dip Needle offers durability and accuracy. These materials enhance the devices performance while minimizing maintenance. Its sturdy build ensures long-term reliability in laboratory environments, making it ideal for routine and advanced scientific applications.

Analog Display for Reliable Measurements

The analog display allows for precise and easy observation of readings without the need for digital interventions. This straightforward design ensures users can interpret results quickly and accurately, providing confidence in laboratory analysis and research tasks.

Designed for Laboratory Use

With a working temperature range of 10-40C and a capacity of 1 kg/hr, the Dip Needle meets the demands of diverse laboratory environments. Its compact size facilitates convenient placement and operation, making it highly adaptable for various experimental setups.

FAQs of Dip Needle:

Q: How is the Dip Needle used in laboratory settings?

A: The Dip Needle is placed within the magnetic field to measure magnetic inclination or dip. Its analog display allows for direct observation of readings, making it suitable for educational demonstrations and research activities in laboratories.Q: What materials are used in the manufacturing of the Dip Needle?

A: This model is constructed from high-quality iron and Bakelite, providing both durability and resistance to laboratory conditions, thus ensuring accurate and dependable performance.Q: When should the Dip Needle be operated within its temperature range?

A: The device should be used between 10C and 40C to maintain optimal accuracy and prevent potential damage or measurement errors during laboratory procedures.Q: Where is the Dip Needle manufacturer and exporter located?

A: The Dip Needle is manufactured, exported, and supplied from India, ensuring compliance with international standards and reliable global distribution.Q: What is the process for taking measurements using the Dip Needle?

A: Simply position the Dip Needle in the magnetic field area being studied, then use the analog display to read the magnetic dip or inclination. The stable mechanism ensures consistent, repeatable results.Q: What are the benefits of using an analog Dip Needle over a digital one?

A: Analog Dip Needles provide immediate readings without the need for electronic components, reducing the risk of technical faults. They are ideal for laboratory environments where reliability and ease of use are essential.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Physics Lab Instruments Category

PHOTO CELL CHARACTERISTICS APPARATUS

Price 18000 INR / Piece

Minimum Order Quantity : 1 Piece

Dimension (L*W*H) : 260 x 165 x 125 mm (Approx.)

Equipment Materials : Powder Coated Metal Enclosure, Glass Tube Photo Cell, Brass Terminals

Weight : Approx. 3 kg

Usage : Demonstration and Study of Photoelectric Effect

PLANKS CONSTANT APPARATUS

Price 18500 INR / Piece

Minimum Order Quantity : 1 Piece

Dimension (L*W*H) : 250 mm x 180 mm x 90 mm

Equipment Materials : Highgrade metallic body, durable optical components

Weight : Approx. 2.5 kg

Usage : Measurement and determination of Plancks constant

Sonometer

Price 2350 INR / Piece

Minimum Order Quantity : 1 Piece

Dimension (L*W*H) : Approx. 100 x 18 x 12 cm

Equipment Materials : Hardwood base with brass fittings, steel wires, metallic bridges and pulley

Weight : Approx. 2.5 to 4 kg (varies by model)

Usage : Demonstration of laws of vibrating strings, measurement of frequency, and verification of laws of transverse vibrations

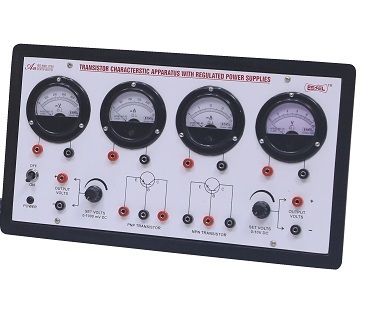

Transistor Characteristics Apparatus with Regulated Power Supply

Price 6200 INR / Piece

Minimum Order Quantity : 1 Piece

Dimension (L*W*H) : 14*12*6 Centimeter (cm)

Equipment Materials : Iron & Bakelite

Weight : 2500 Kilograms (kg)

Usage : For Laboratory

|

ESEL INTERNATIONAL

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry